CUT 1600 Series

Holders For CUT 1600 Series Micro Turning Inserts

The multidec® micro turning and cut-off system for the Utilis® CUT 1600 Series is suitable for Swiss type lathes up to a maximum of Ø10mm in bar diameter. This series includes a large selection of cutting geometries with assorted chip breakers, specifically designed for small parts manufacturing.

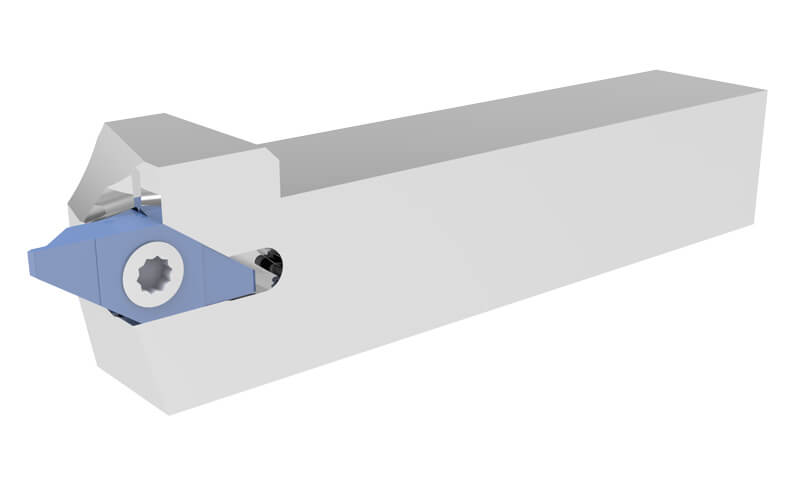

Universal 1600 Series Holders are built to fit all 1600 Cutting Inserts. The pocket is the same across the whole system and provides geometries for cut-off, front-turn, back-turn, grooving, threading and chamfering. GenSwiss carries standard square shank tool holders, both with and without internal cooling, plus specialty holders designed for specific turning applications.

|

|

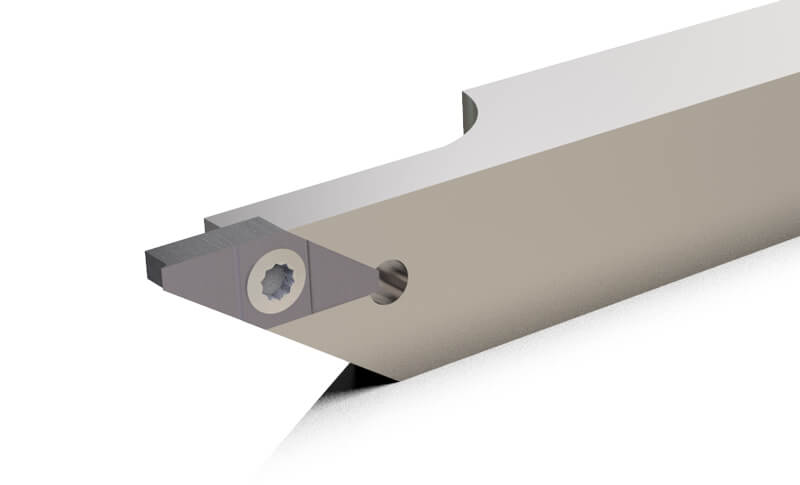

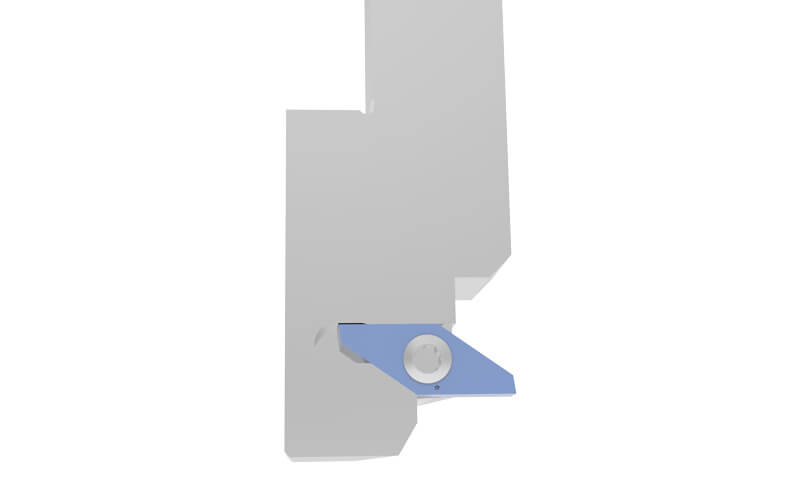

| Insert pocket geometry on all CUT 1600 series holders both locates and protects the insert. | Standard square shank standard and specialty holders provide holding solutions for all turning application needs. |

Standard Holders‣ Straight square shank holders that hold every major geometry type

Standard Holders‣ Straight square shank holders that hold every major geometry type

‣ Available in coolant-thru and non coolant-thru

‣ Holders with shifted inserts and built-in clearances for cut-off and grooving

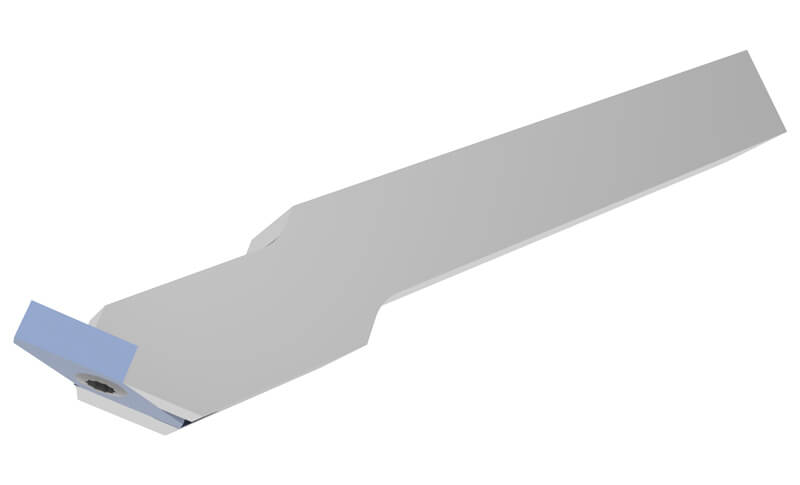

Learn More & Buy Face Grooving And Turning‣ Holders that angle the insert geometry for face grooving and turning operations

Face Grooving And Turning‣ Holders that angle the insert geometry for face grooving and turning operations

‣ Available in coolant-thru and non coolant-thru variants

‣ Round and square shank variants available

‣ Some holders require opposite insert handedness

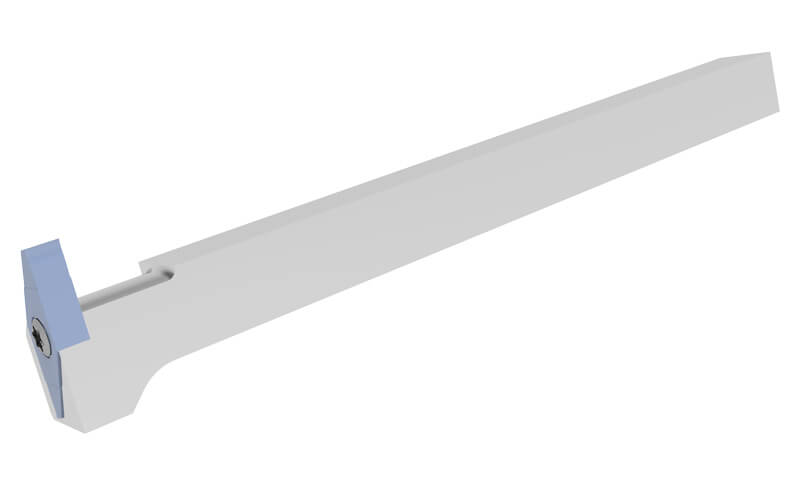

Learn More & Buy ID Grooving And Turning‣ For ID grooving and turning features

ID Grooving And Turning‣ For ID grooving and turning features

‣ Available in coolant-thru and non coolant-thru variants

‣ Round and square shank variants available

‣ Some holders require opposite insert handedness

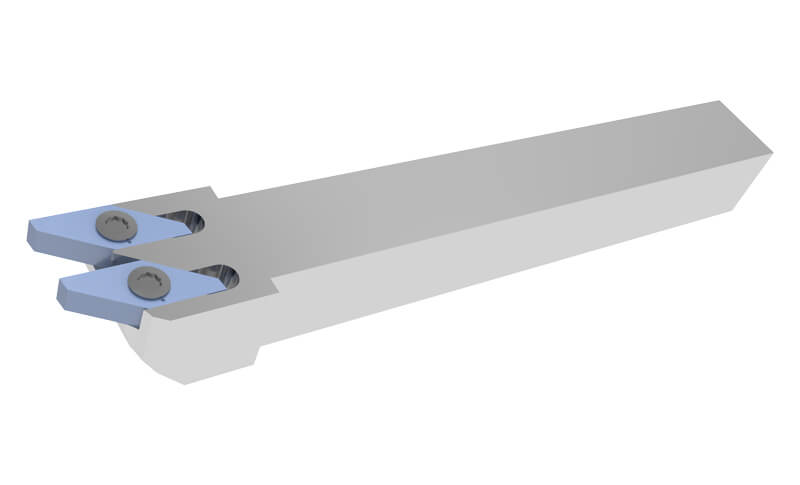

Learn More & Buy Twin‣ Double the work capacity of a single operation or double the capability of a tool position

Twin‣ Double the work capacity of a single operation or double the capability of a tool position

‣ Available in coolant-thru and non coolant-thru variants

‣ Run two CUT 1600 Series inserts or one CUT 1600 Series insert and an ISO TOP insert

‣ For max bar stock diameters 11.5-34.0mm

Learn More & Buy Y-Axis‣ Prevent bird-nesting and chip wrap when removing a significant amount of material

Y-Axis‣ Prevent bird-nesting and chip wrap when removing a significant amount of material

‣ Available in coolant-thru and non coolant-thru variants

‣ Use for any turning operation but excels during front and back turning

‣ Superb chip control on stringy materials

Learn More & Buy multidec Short‣ Enables the use of CUT 1600 series inserts on commonly available quick change tool systems

multidec Short‣ Enables the use of CUT 1600 series inserts on commonly available quick change tool systems

‣ Coolant-thru capability enabled through universal coolant plumbing or through the quick change tool system's internal cooling solution

Learn More & Buy Enhanced Cooling‣ Holders that feature coolant jets along the clearance angle in addition to the traditional cutting edge coolant jets

Enhanced Cooling‣ Holders that feature coolant jets along the clearance angle in addition to the traditional cutting edge coolant jets

‣ Extends the tool life of CUT 1600 and CUT 3000 series turning inserts

Learn More & Buy